Concrete X-Ray

WHAT IS Concrete X-Ray?

Concrete X-Ray is the term commonly used to describe the process of scanning concrete floors, slabs, concrete masonry unit (CMU) walls, concrete columns, and other concrete structures. Specific construction and inspection requirements demand concrete scanning. However, most modern-day concrete scanning is done using GPR technology not X-Ray.

Hidden hazards can be avoided by X Ray or GPR scanning before saw cutting or core drilling. Many concrete or masonry structures are formed using steel rebar reinforcement or post-tension cables (PTC). Drilling or cutting into a PTC slab, or a rebar reinforced structure, could cause catastrophic and costly damage. Predetermining the location of PTC, rebar, or other hidden utilities in concrete using X-Ray or GPR scanning ensures a safe core drilling location .

If you are looking for X-Ray scanning to prepare for concrete core drilling, the best approach is GPR scanning vs. X-Ray.

Benefits of GPR Scanning over Concrete X-Ray

- GPR scanning reveals the location of the rebar and cable in real-time. Concrete X-Ray requires post-processing off-site.

- Rebar and cable locations are marked during the GPR scanning process. X-Ray locations not marked in real-time.

- Only access to the top of the slab is required for GPR scanning. X-Ray needs access to the top and bottom.

- GPR is a fraction of the cost of X-Ray.

- GPR scanning can be done during business hours with people present. People should not be nearby during X-Ray operation.

- GPR does not emit harmful radiation.

the gpr scanning process vs. x-ray

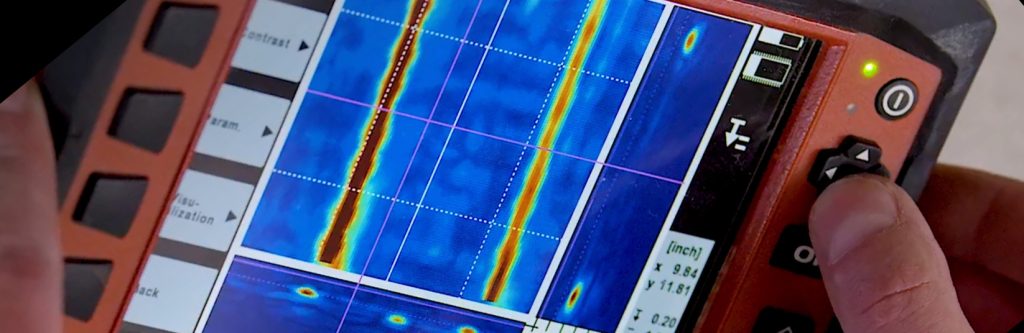

Concrete X-Ray is rarely the best approach when scanning a slab for rebar and PTC detection. We use the Hilti PS 1000 Ground Penetrating Radar Scanning System (GPRS) in order to locate rebar reinforcement steel, tendons, metal, voids in dry concrete structures and floors at depths of up to 300 mm or 12 in.

our scanning process

- Our technician arrives at the job location and reviews the scope of work.

- The scanning locations are reviewed and verified.

- The area is identified and tagged with a unique identification number corresponding to a scanning record.

- The Hilti PS 1000 GPRS is powered on and a diagnostic check is conducted.

- The scanning machine is manually traversed across the grid until the initial first target is identified.

- Following the scan image, the location of the target cable or rebar is marked on the slab surface.

- This process continues until all rebar or PTC markings are outlined orthogonally above the slab.

- The scan is recorded to the onboard system solid-state memory.

- The process is repeated for all job site locations.

- For concrete core drilling projects, the drill location is precisely marked followed by the core drilling process.

- The Hilti PS 1000 is returned to the Specialized Testing lab and the scan data is downloaded.

- A report is created showing scan detail and core drilling locations.

In the images above the rebar reinforcement steel locations are marked in yellow indicating their location. To produce the same result using concrete X Ray we would need an X-Ray machine on the slab surface firing gama radiation isotopes, and film beneath the slab. Since this slab is on grade, access below the slab is impossible.

Where this scan took approximately 2 hours to complete X Ray scanning would take closer to 16 hours. This area was scanned with personnel nearby during daytime hours. To reduce radiation exposure for long scan durations, this same scan using X Ray would need to be done after hours or when the location was vacated.

when is concrete x-ray better than GPR?

In some cases, X-Ray may be a better choice to scan a concrete structure.

A concrete X-Ray can produce the same type of detailed image we see in a medical office. When it is critical to see the detail of objects in a concrete floor and not just identify the location, X-Ray images produce better detail. However, even with X-Ray technology, there are limitations. For example, somebody must place a film tray directly below the concrete and X-Ray machine above.

X-Ray can scan through as much as 24″ of concrete. To capture images at such depths, special gamma radiation isotopes must be used and require lengthy exposures. One 14″ x 24″ scan can take over 8 hours.

The Latest Technology - 3D GPR

3D GPR Pros and cons

- Non-destructive like X-Ray and GPR

- Produces a 3D image of embedded objects

- Shows precise depth of scanned objects

- Shows relative positions of hidden objects

- Requires specialized equipment

- 3D GPR costs more than traditional GPR

OUR Concrete X-Ray SERVICE (GPRS)

PROFESSIONAL

Concrete X-Ray

AND STRUCTURAL INVESTIGATION

Using the Hilti PS 1000 Ground Penetrating Radar Scanning System our team will come to your job-site and reveal the exact location of concealed rebars, tendons, metal and plastic conduits, glass-fiber cables, voids and wood in dry concrete structures at depths of up to 12″ or 300 mm.

Our service will help minimize the chances of hitting concealed objects while drilling anchor holes or through holes, breaking out openings and in diamond coring and sawing work.

Our Radar Scanning is also ideal for the inspection of floors, decks, slabs, balconies, concrete columns and other structures such as tunnels, bridges and buildings.

Unlike other X-Ray scanning companies Specialized Testing can also conduct core drilling and rebar exposure during the same site visit and provide detailed reporting.

Concrete Scanning Projects

Satisfied Customers

Concrete GPR Scanning Case Studies

Kipp endeavor College prep

I. REFERENCE:

12421 S. Soto St., Los Angeles

SPECIALIZED TESTING REPORT

NO.: STSI92493

II. PURPOSE:

The client requested concrete x-ray scanning to locate and expose in-place reinforcement steel exposure. Structural Investigation scope of work using Ground Penetrating radar over x-ray scanning was developed.

Radar (GPR) and by performing Reinforcement Exposures in two buildings. Thirty-Two (32)

Instead of X-Ray, GPR Scans and Twelve (12) Reinforcement Exposures were performed.

Test raw data is presented in Attachment 1. Test locations are presented in Attachment 2. Field

III. TEST APPARATUS AND PROCEDURE

- Thirty-two (32) wall locations were scanned to determine if reinforcement was present and to determine the spacing and orthogonal direction of the reinforcement located. The thirty-two (32) scans were completed on two buildings.

- After the reinforcement spacing was determined, twelve (12) small areas were opened to expose the reinforcement to be able to determine the bar size and whether it was partially or fully grouted.

- Pilot holes, 5-10 per scan, were drilled to further verify visually if the wall was partuially or fully grouted.

what's the difference between concrete x-ray and GPR?

Concrete x-ray and ground penetrating radar are two commonly used methods for locating objects and voids within concrete structures. Both techniques are non-destructive and provide valuable information about the internal structure of concrete.

However, there are some differences between the two methods that are important to understand.

The biggest difference between the two scanning technologies is that X-ray scanning requires a detector or film on the opposite side of the emitter. When scanning concrete slabs and structures, placing a detector on the other side of the emitter is impossible.

For example, most concrete slabs are built on grade, and there is no feasible way to reach the underside of the concrete. For this reason alone, GPR scanning is the only technique available.

OUR Concrete X-Ray SERVICE

Concrete X-Ray SERVICE

Using the Hilti PS 1000 Ground Penetrating Radar Scanning System our team will come to your job-site and reveal the exact location of concealed rebars, tendons, metal and plastic conduits, glass-fiber cables, voids and wood in dry concrete structures at depths of up to 300 mm.

Our service will help minimize the chances of hitting concealed objects while drilling anchor holes or through holes, breaking out openings and in diamond coring and sawing work.

Our Radar Scanning is also ideal for the inspection of floors, decks, slabs, balconies, concrete columns and other structures such as tunnels, bridges and buildings.

Satisfied Customers

OUR Concrete X-Ray SERVICE

Concrete X-Ray SERVICE

Using the Hilti PS 1000 Ground Penetrating Radar Scanning System our team will come to your job-site and reveal the exact location of concealed rebars, tendons, metal and plastic conduits, glass-fiber cables, voids and wood in dry concrete structures at depths of up to 300 mm.

Our service will help minimize the chances of hitting concealed objects while drilling anchor holes or through holes, breaking out openings and in diamond coring and sawing work.

Our Radar Scanning is also ideal for the inspection of floors, decks, slabs, balconies, concrete columns and other structures such as tunnels, bridges and buildings.

Satisfied Customers

Our Certifications and accreditations

Why choose Specialized Testing for your Concrete X-Ray?

We have the experience, Qualification and Expertise to handle your Next Project

Ready to get started?

Contact Us Today for Concrete X-Ray

About specialized testing

Your source for Material Testing, Concrete testing, Concrete X-Ray / GPR Scanning, Field Testing, & Product Qualification testing.

For over 30 years Specialized Testing has been providing nation-wide product certification testing and throughout California and the Southwest, Concrete Testing and X-Ray Scanning Services. Our primary mission is to ensure the safety of and integrity of job sites and products throughout the US.

For over 3 decades we have served thousands of customers and offered reliable services and the highest quality results.

Specialized Testing is a full-service lab specializing in the testing of rebar, concrete and masonry materials. We provide services to engineers, inspectors, and construction professionals. Located in the City of Santa Fe Springs we are an approved testing facility by the ACI (American Concrete Institute) and the City of Los Angeles. Serving Los Angeles County, Orange County, San Bernardino, and Riverside County we are committed to providing our services in a timely and professional manner. We pick up all sample specimens within 48-hours of notification and aim to provide lab results within three days of initial test.